Business

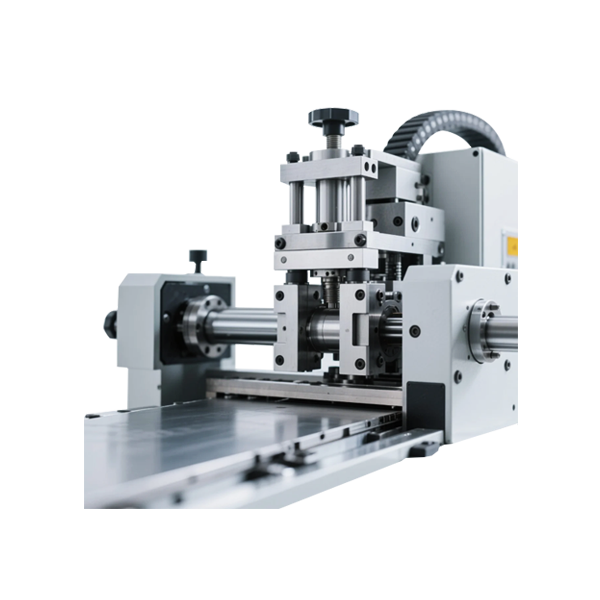

Insulation Cutting

Equipped with an automatic die-cutting processing workshop, it can die-cut various insulating materials, EM shielding materials, 5G thermal conductive silicone grease gaskets, aluminum foil, copper foil, thermal conductive double-sided tape and other punching products. The products are widely used in transformers, motors, power batteries and other industries